Descending window

The vertical highlight

At the touch of a button, the entire window front sinks into the floor as if by magic, allowing the interior to merge with the exterior – with absolutely seamlessly. The advantage over a sliding window front: The slider does not have to be pushed in front of a fixed element. This allows the entire window façade to be opened.

Sufficient space underneath the glazing is required for a technical room to position the descending window in the open state. The controller, motor, drive shaft and counterweight are also housed here.

Unique sealing system –

how air-lux works

Descending window

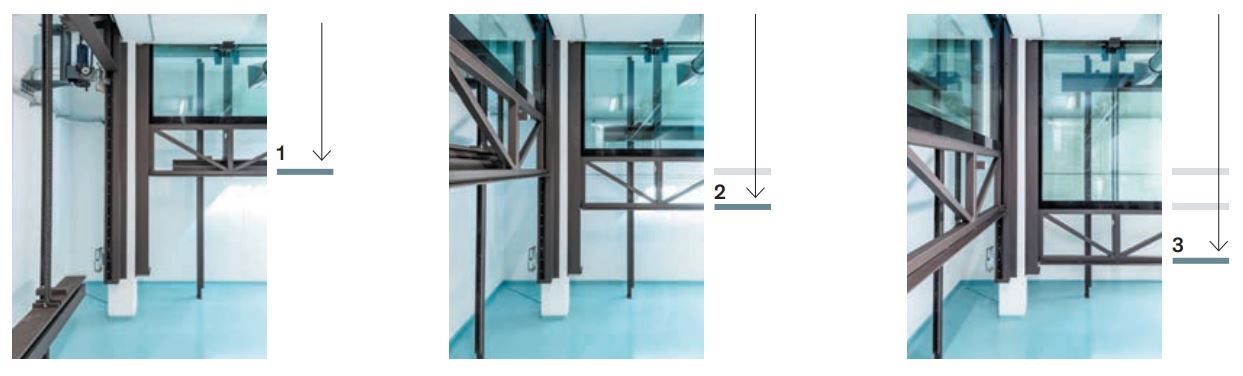

The unique air-lux sealing concept with all-round inflatable ring seals guarantees 100% impermeability against driving rain, wind and noise.

Open window:

the seal is vented at the touch of a button. After unlocking and venting, the glass wall disappears silently into the floor by a constant push of a button.

Close window:

the descending window is closed by a constant push of a button. As soon as the window frame is completely closed, the LED in the button goes out and air is pumped into the seal.

Features of the air-lux descending windows

Construction

The moving parts are raised and lowered silently by means of an electric drive. In the event of a power failure, the descending window can be closed manually from the technical room.

As the descending window disappears completely into the ground, enough space beneath the glazing must be available to accommodate it when open. This technical area includes the control, motor, drive shaft and the counterweight, and must be accessible for maintenance work. The dimensions of the technical area are determined and logged by air-lux.

Operation

The window functions are operated by a button with a deadman’s switch and visual monitoring of the movement. The buttons are activated via a key switch. This prevents unauthorised people from operating.

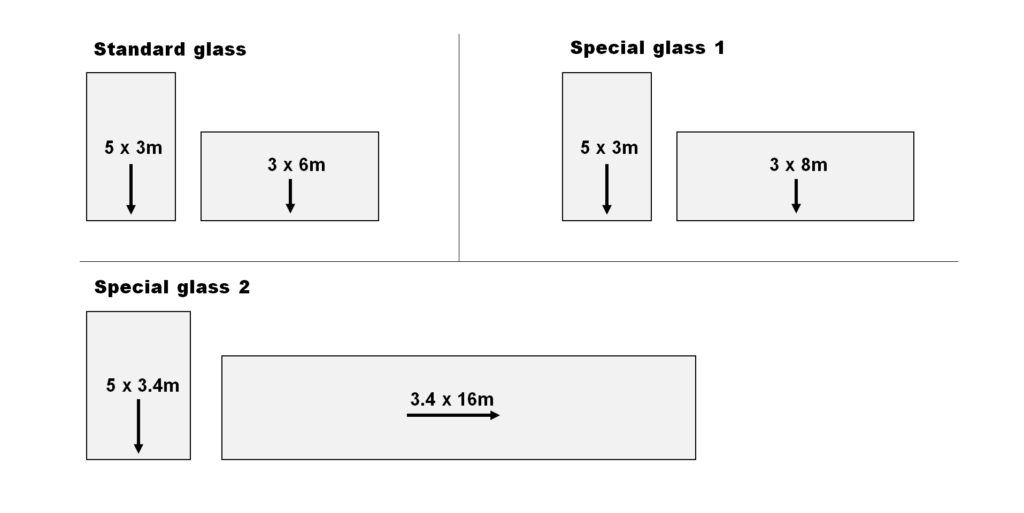

Sizes and weight

Surfaces and materials

Whether a special wood, architectural bronze or stone, We produce sunken windows in different real materials and surfaces. The core is always our high quality, thermally insulated aluminum profile clad with the required material.

Safety

We manufacture and assemble the air-lux project in compliance with the machine guidelines. This means that personal protection is guaranteed at all times, whether during the operation of the descending window, during a power outage or in severe weather conditions.

Glass to a thickness of 60 mm can and bullet-resistant safety glass can also be constructed.

Cross-sections

Brochures and videos

Brochures

Videos

Animation descending window

Descending window

Sample descending window

Nietturm Zurich

Instructions

Operating instructions descending window

Originalbetriebsanleitung für Senkfenster

Original instructions for descending windows

Manuel d’utilisation original pour fenêtres descendantes

Istruzioni originali per vetrata a scomparsa nel pavimento

Originele gebruikershandleiding voor verzonken raam

Originálny návod na obsluhu výsuvných okien

Originální návod k použití pro spouštěcí okno

Окно опускания руководства по эксплуатации

升降落地窗的原版使用说明书

Cleaning instructions

SZFF Policy

Tender text

This content will be available shortly.

Accessories

From special surfaces to exclusive materials, air-lux descending windows can be customised with a wide range of different options. And, of course, the air-lux descending windows also offer burglary protection and an alarm package – safe is safe.

Awards for the air-lux window

Contact

Send us an email, give us a call, challenge us. We will be happy to help you.